Født ved havet

formet av bølgene

In our portfolio, we have several solutions for adding oxygen to cages and vessels. Injectors for oxygen enrichment of the water flow, the Oxygen ball which is very easy to handle and perfectly suited for emergency operations and NetOx which is well suited for larger areas. NetOx Net is a diffuser network that supplies oxygen to cages at low oxygen levels, to reduce fish stress and ensure better feed utilization and growth. NetOx is the most widely used diffuser hose for emergency oxygenation in Norwegian fish farms.

Oxygen and growth

Research has shown that in certain periods of the year, periodic oxygen shortages can occur in marine facilities. Such conditions usually occur in late summer and early autumn when the water temperature is high and there are many fish in the cages. Oxygen deficiency is most common in the dark part of the day. Temporary lack of oxygen in the cages can also occur in other parts of the year. At unfavorable oxygen levels in the sea, an increase of only 5–10% dissolved oxygen can result in more than 10% improved growth. Adding oxygen periodically will therefore be profitable and ensure good fish welfare.

Easy to use

Both the Oxygenkulen and NetOx are very easy to use. The sphere can easily be lifted into place with, for example, a crane or lowered from a buoy, with only a hose for oxygen-enriched seawater going down to the sphere. NetOx Net is a hose-based diffuser that can be connected according to the design of the cages. The system is equipped with high-quality threaded connections in acid-resistant AISI 316 and can be equipped with solder in acid-resistant steel. NetOx Net is robust and designed for rough conditions.

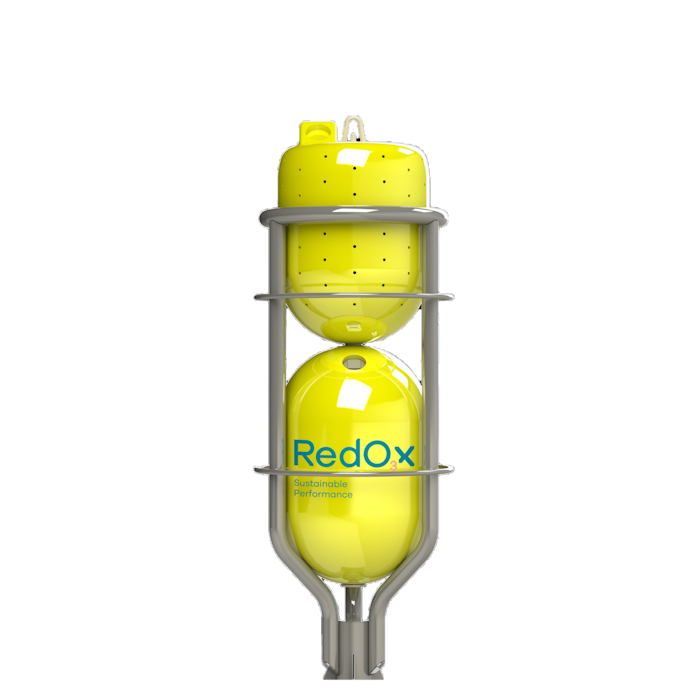

Oxygen Ball – adds 25-40 kg / O₂ per hour

Due to high demand from our customers, Redox has developed the Oxygen Ball to maintain a healthy oxygen level during fish farming. The Oxygen Ball is designed to efficiently infuse oxygen into the net pen by using injected seawater. It is also easy to move and can be used as a weight to keep the harvest net away from the fish pumps.

Benefits of oxygenation during crowding:

- Lower mortality rate

- Improved gill health

- Increased appetite after treatment

- Increased growth rate

Using an injector ensures a good dissolution of oxygen in water. The Oxygen Ball disperses water with a high oxygen saturation, which easily mixes with the surrounding water in the net pen. This ensures rapid oxygenation without significant oxygen loss in the form of bubbles floating to the surface and transferring to the air.

Venturi Injection

Redox has extensive experience in the use of injectors for various purposes in aquaculture. Injector pumps are used to add oxygenated water to wells in wellboats and through the Oxygen Ball in the harvest net. Injector skids are low-footprint solutions that have the capacity to add large amounts of oxygen through a sidestream, which is then supplied to the production unit. The oxygen is drawn into the injector and mixed with the water, and then the oxygenated water is dispersed to the production unit through a nozzle, resulting in even better mixing.

Benefits of an injector:

- Good mixing and efficient oxygenation

- Minimal oxygen loss at the surface

- Occupies minimal space in the production unit, whether it’s in a cage, tank, or well.

- Designed for automatic regulation of oxygen supply.

Diffusion – NetOx by Bio Marine

The NetOx Pod is a compact diffuser specially developed for supplying large quantities of oxygen or air (circulation) in aquaculture volumes. It is available for use with oxygen and air separately or in combination.

Benefits of NetOx:

- Easy to regulate

- Uniform distribution within the cages

- Efficient microbubbles

- Easy to move from cage to cage

- High capacity

- Compact and tidy design

Want to know more?

What can we help

you with?

We’d love to hear from you!

Do you have any questions about any of our products or services? Feel free to send us an e-mail – or contact one of our talented employees directly!